-

PRODUCTS

-

-

SERVICE SUPPORT

-

ABOUT

Automotive Industry Solutions

With the full promotion of Industry 4.0, industrial Internet products are increasingly widely used in the automotive industry, including logistics AGV scheduling, robot control, conveyor line control, cloud command, cloud monitoring, data acquisition and analysis, and so on.

In the application of the automotive industry, the main technologies involved are data acquisition, remote monitoring, remote scheduling and other aspects, for which industrial Internet products provide a reliable and stable communication guarantee. The automotive industry is facing industrial upgrading of digitalisation, informatisation and modernisation, and the introduction of industrial internet technology in the production link of the whole industry will provide high-quality resource integration for the automotive industry chain and comprehensively improve the scale and efficiency of automotive production.

Industry pain points

1. Complex wiring of production line networking equipment

Cumbersome manufacturing and assembly process steps, high production costs

2.Interruption of automated production system

Network disruption affects the assembly quality and testing accuracy of automotive parts.

3.Delayed communication and unstable network

Untimely data transmission, affecting the coordination and response of the production process

4. Limited remote monitoring and maintenance

Poor network affects real-time monitoring of production lines and testing accuracy.

Translated with www.DeepL.com/Translator (free version)

Solution Overview

KAXA provides a complete set of solutions in the field of logistics, distribution and industrial control for the pain points of the automotive industry, including logistics AGV scheduling, robot control, conveyor control, data acquisition, remote monitoring, remote scheduling, etc., which can solve the problems of wide construction area, high cost, inconvenient maintenance and unstable effect for the customers. Through the stable and high-speed network connection, real-time transmission of key data, to achieve seamless interconnection of vehicles, equipment and production lines.

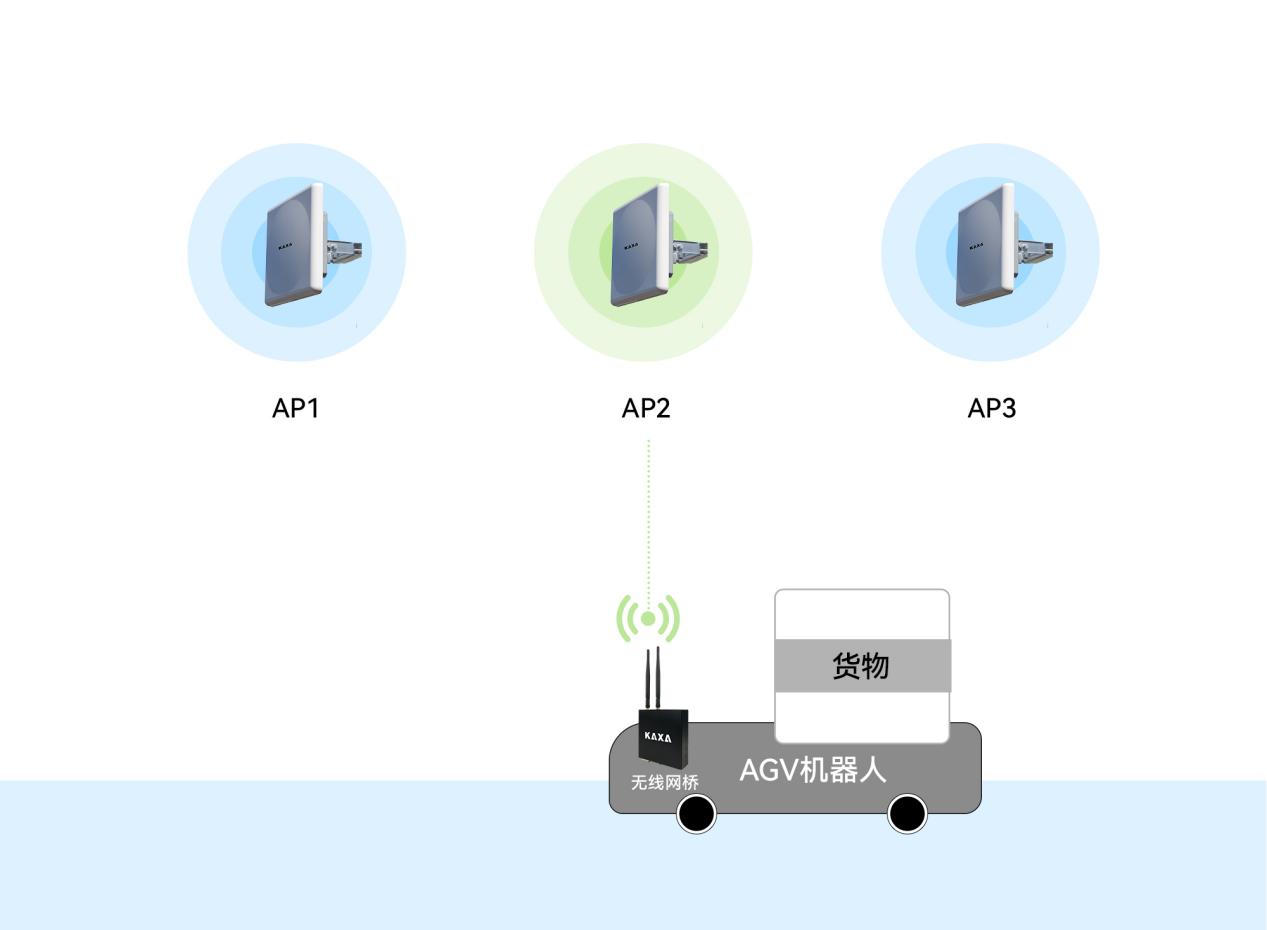

KAXA selected KXC1100 series wireless bridge and KXA5100 series wireless AP access point for an automobile factory in Hangzhou, with kaxa industrial switch, to provide efficient network connection for the workshop, to achieve seamless interconnection of vehicles, equipments and production lines through stable and high-speed network connection, efficient real-time control, fast fault warning, and provide efficient and fast interconnection channel for production data and monitoring data. interconnection channel for production data and monitoring data.

KXA5100 series wireless AP access points provide flexible network access for AGV dispatching and mobile devices, reducing wiring costs and construction difficulties, while ensuring the stability of network connection and high-speed data transmission.

KXS 205/208 industrial switches support a variety of network protocols and interfaces, enabling the integration of different production equipment and systems (e.g., PLCs, robots, sensors, etc.) into a unified network to ensure real-time data transmission.

Enhanced roaming for seamless AGV cart connectivity

Previous

Next

MAIN PRODUCTS

DOWNLOAD

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.